Challenge

To produce finished goods at Batten&Allen, raw material purchased from suppliers is processed up to 4 times. During this, stock codes are transformed to intermediary (WIP) stock codes with batch numbers used to track physical stock. To meet the traceability requirements of ISO 9001, it is necessary to issue a Batch Trace Report with every dispatch. However, their existing 123Insight system does not support this functionality, meaning every dispatch required a time consuming and repetitive administrative process.

Our Solution

During every batch receipt, operators are required to note in a free text field of their existing shop floor data capture (SFDC) app the batch numbers of the raw material or partially finished goods consumed during the production of the current batch. To save time, full batch numbers ‘BN/0000001, BN/0000002’ can be abbreviated as ‘1, 2’.

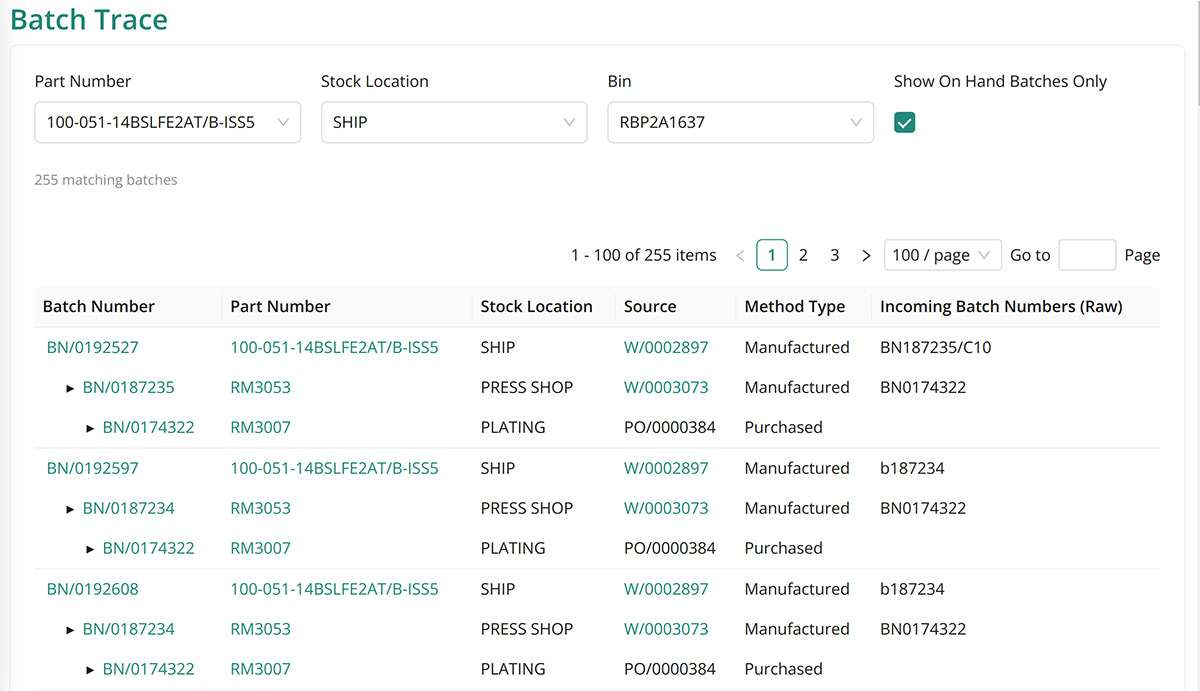

Operation Software built a Batch Trace Module in Batten&Allen’s OperationalPlatformᵀᴹ. This module enables the filtering of batches by stock code, current stock location and bin, so batches in a specific dispatch can be identified. Automatically, a recursive batch trace process runs which identifies the batches consumed in the production of each batch and displays them as a visual tree structure. From here, the information can be reviewed by the dispatch department. Any erroneous information entered during production investigated and amended to ensure an accurate Batch Trace Report.

Finally, the user can click a button to generate the report as a company branded PDF document utilising a custom HTML template and the HTMLtoPDF OperationalPackageᵀᴹ which is issued along with other dispatch documentation.

ANNUAL RETURN ON INVESTMENT

With approximately 1,000 dispatches, the estimated return on this module stands at £5,000 per annum in time savings alone.

Other benefits include:

Conformance to ISO 9001 traceability – a key selling point in winning new business.

Reduced opportunity for errors to operator input alone (future plans are in place to reduce this further).

No duplicate data entry.

Highly visual display of Batch Trace Report for ease of review and amendment.

Dispatch staff time released to focus on more complex business problems.